Hardware:

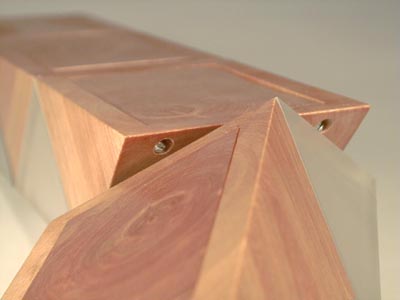

I wanted the lamp to have as little visible hardware as possible. The covers to the wooden sections are held on with four "hidden" screws that are revealed as the sections are turned. The acrylic section covers are held on with two small machine screws. These screws can only be accessed by removing the abutting wooden sections.

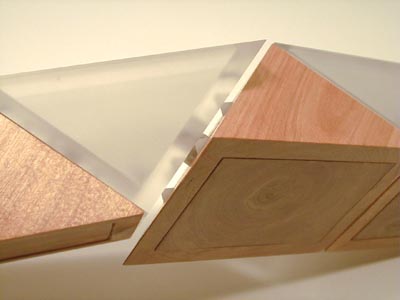

You'll note that both types of section were machined hollow from solid blocks of material. This increases strength and eliminates unsightly seam lines that would've resulted from joining separate wall pieces. A sandblasted interior creates translucence to obscure the 10W Xenon bulb and wires contained in each acrylic section.

Revealed hardware.

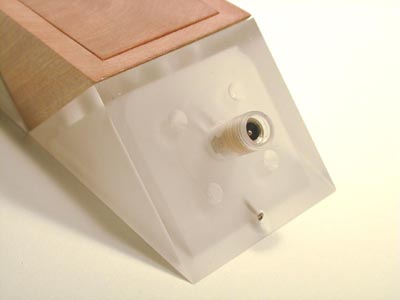

Translucent acrylic blocks.

Electrical Supply:

Probably the most daunting task was that of supplying electricity to the rotatable sections. Running a cord through the sections would've been easy, but that would've eventually caused coiling problems. Ideally, the user would be able to freely rotate any section indefinitely.

Initially, I thought this would be a simple matter of using any small, commercially-available rotatable connector. The problem was, there's no such thing. Hard to believe, but I called many electrical supply companies to no avail.

Ultimately, I solved the task by using a "DC power plug/jack." This plug is similar in design to the jack and plug found on any Walkman. You'll recall that you can rotate your headphone jack around in the plug with no break in sound.

It was unrealistic to expect that the user would always precisely rotate the sections about their axes. Some non-axial stress or "tweaking" was bound to occur. I realized that if all the mechanics were rigidly affixed, something would have to break once such stress occurred. I decided to secure the male jack with a piece of thick rubber. This "soft mount" permits some flex in the operation of the sections, while still ensuring that the jack remains joined to the plug. The photo to the right shows one of the jacks plugged in and the other out.

Female connectors cemented in axial cylinders.

Male connectors (one attached, one exposed)

Indexing/Tension:

To work well, each section face needs to be square to the adjoining faces. If one section is not square, that will prevent rotation of neighboring sections. Thus, I felt the sections should be indexed so that user would always be sure they had turned a multiple of 90 degrees.

Using a lathe, I created tapered ends on the ends of some nylon screws. These screws would thread from inside to outside of a section and would mate with corresponding tapered holes on the next section. Small sections of a strong spring ride around the plug/jack stem and pull the sections towards one another. The beauty of the coned screws is that the user doesn't need to "fight" the spring tension - they simply rotate a section, the coning causes the section to rise up and out of the index holes, eventually resettling into the next orientation when it's turned far enough.

Indexing nipples.

Indexing recesses.

Spring tension provides a nice "snap" on the detents.